Customized Services

Thanks to its laboratory, the company guarantees an important analysis service that allows it to: identify the causes behind the issues at hand, recommend the best products for each specific application, and monitor the lifetime of the lubricant, thus avoiding unpleasant machine downs.

The Syneco laboratory

The Syneco laboratory is equipped with sophisticated instruments:

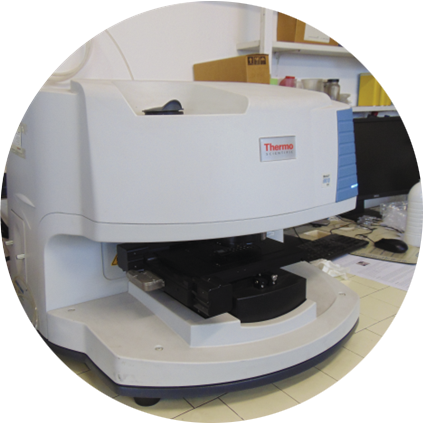

Spectrophotometer FT- IR (PERKIN ELMER) used to determine the IR layout, the Cetane number and biodiesel contamination;

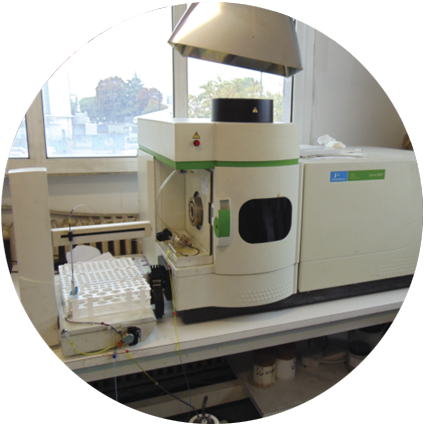

ICP emission Spectrophotometer (PERKIN ELMER);

Automatic Titrator for the determination of TAN;

Thermostatic Bath for the determination of the Cloud Point;

Electronic microscope;

Automatic viscometer for the determination of lubricant viscosity;

Millipore filtration system.

Analyses

The laboratory offers 5 types of analyses that meet the different needs of clients:

COMPARATIVE ANALYSIS:

it is carried out on a sample of new lubricant to verify its composition and suggest the equivalent Syneco product;

SERVICE 2000 – PROFESSIONAL CONSULTING:

an analysis of the mechanical components (filters, injectors, pumps, brass bearings, etc) to determine the causes of the issues that were spotted by the client;

SERVICE CHECK UP:

preventive maintenance analysis to determine the lifetime of the lubricant and potential application issues;

INTEGRATE SERVICE:

analysis of used motor oils in comparison with the new ones at hand. This analysis allows us to identify and define foreign elements in the fluid;

HOT SERVICE:

a filtration and regeneration process aimed at prolonging the duration of the hydraulic oil in service.

Laboratory instruments

AUTOMATIC VISCOMETER SVM 3001

The viscometer analyzes up to 60 samples of oil automatically in just a few minutes by measuring: the kinematic viscosity at 100 and 40 °C, the viscosity index, density at 15 °C and dynamic viscosity with temperature scans that can vary from – 45 to + 140°C.

ICP EMISSION SPECTROPHOTOMETER (PERKIN ELMER)

This instrument identifies the elements present in the lubricant determining the additivation of the product, the polluting elements and the quantity of metals. The fluid that must be analyzed is suctioned, nebulized and burned with a flame at about 4000 °C. Each element emits a certain energy and wavelength so that the optical system can identify the element and how much of it is in present in the fluid.

FT-IR SPECTROPHOTOMETER (PERKIN ELMER)

The lubricant that must be analyzed is placed in a diamond or zinc selenide anvil and pierced by an infra-red ray. Depending on the bonds between molecules a certain amount of energy is absorbed at a certain wavelength. This produces a diagram that identifies the fluid. With this method, its nature can be identified in addition to calculating the cetane number, the biodiesel content and the pollutants.

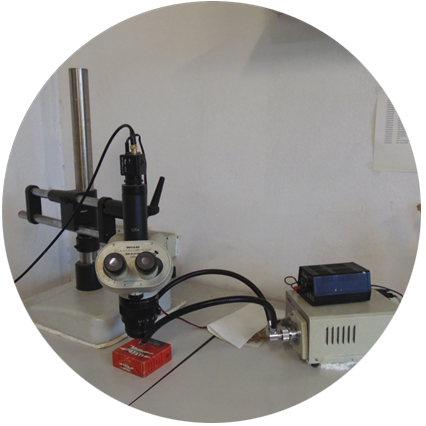

FT-IR ELECTRONIC MICROSCOPE

The electronic microscope is associated to a FT-IR spectrophotometer. This way, solid particles, fibres and elastomers can be analyzed, thus determining their nature.

OPTICAL MICROSCOPE

The instrument allows us to analyse the particles present on filtering membranes and to measure their size. In addition, the deposits in the fluids are photographed.

CALLISTO 100

With this instrument we calculate the ‘pour point’ (the freezing point of the lubricants) The oil is put in a cylinder and brought to 9 °C above its hypothetical freezing temperature, then the temperature is lowered by 3 degrees at a time and we visually check if the fluid has reached its freezing point. In addition, the CFPP of diesel oils is calculated.

VISCOMETER BATH

This instrument is used to measure viscosity at 100 and 40°C. The fluid that must be analyzed in placed in the capillaries and then immersed in the bath. Viscosity is calculated according to the ASTM D445 method.

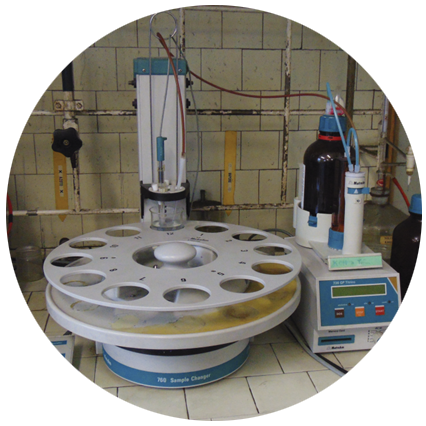

AUTOMATIC TITRATOR

The instrument carries out the measurement of the Total Acid Number to check the oxidation of the product that is being analyzed through potentiometric titration.

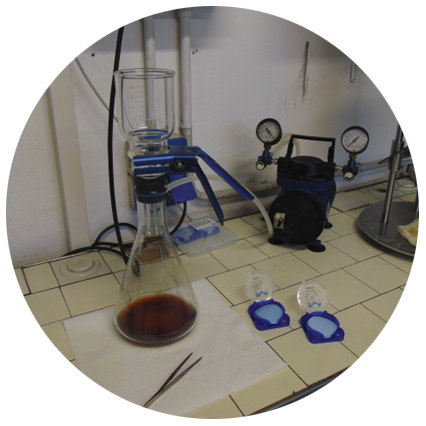

MILLIPORE FILTRATION SYSTEM

The filtration system allows us to carry out a Denison test, in other words filtering 100 cc of sample on a membrane at 1.2 microns at a temperature between 16 and 25°C. This allows us to evaluate if the oil is fliterable or not and, in addition, it allows us to identify pollutants in a used oil.

PARTICLE COUNTER

This instrument determines the level of contamination of a fluid based on the count of the number of particles per volume unit subdivided in size classes. The NAS 1638 and ISO 4406 class of the lubricants is determined.